A four-year ATSB report has identified a catalogue of basic errors made by Malaysia Airlines staff that led to a ‘serious incident’ on a packed A330 at Brisbane.

The aircraft, bound for Kuala Lumpur and carrying 215 passengers, eventually had to turn around mid-air and return home after it was identified too late that the vital airspeed sensors were covered up.

Two similar incidents in 1996 involving 757s led to fatal crashes that killed more than 200 people.

The ATSB said in a statement its investigation into the 2018 incident was “one of its most substantive and complex” in recent years and highlighted poor decisions made by Malaysia Airlines pilots and crew, alongside those from other organisations.

In particular, the report found:

- The Malaysia Airlines flight crew, engineers and dispatch coordinator didn’t conduct the vital pre-departure checks properly, or, in some cases, even attempt them at all;

- The certifying engineer saw the covers were left on early in the turnaround but later “forgot about them”;

- The captain did not “assertively” announce the presence of a problem when it was detected, delaying the first officer’s response. There was then “limited coordination between them” which reduced their ability to interpret the situation and abort the take-off;

- It concluded “several individuals on the night” all acted as though the conduct of aircraft inspections was “someone else’s responsibility”.

The incident took place on 18 July 2018, when the Malaysia Airlines Airbus A330, 9M-MTK, took off from Brisbane bound for Kuala Lumpur in Malaysia, with 14 crew and 215 passengers on board.

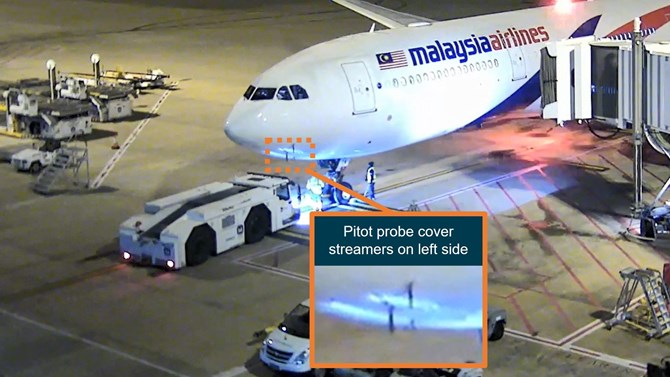

Crucially, the ‘pitot probe’ covers, which act as airspeed sensors, were covered up during takeoff. The covers are necessary at Brisbane airport due to a problem with mud wasps in the area, which can sometimes fly into them.

In total, four walkarounds should have been conducted in the period the covers were on, which should have identified the problem. However, two of these didn’t happen at all, while the Malaysia Airlines’ engineer noticed the covers but then forgot to mention them.

“Had all the relevant pre-flight inspections been completed, and conducted thoroughly, it is very likely that the ‘pitot probe’ covers would have been seen and removed,” the ATSB chief commissioner Angus Mitchell said. “It’s important to treat every safety-related task or inspection as though it could be the last barrier to protect against an accident.”

Because the pitot probe covers were left on, the instruments onboard in the cockpit showed a red speed flag in place of the airspeed indication from early in the take‑off, and, the ATSB said, ‘unrealistically low’ airspeeds afterwards.

However, the flight crew did not respond to the warnings until after the A330’s speed was too high to safely abort the take-off. The flight crew’s initial radio announcement of an ‘urgency situation’ was then not heard by the air traffic controller.

The flight crew climbed to 11,000 feet and circled while performing troubleshooting and other procedures, which led to the shutting down of the aircraft’s air data systems. Doing so activated the backup speed scale (BUSS), a safety function that displayed safe flight envelope information to the flight crew in lieu of airspeed.

Using this system, airspeed management procedures and assistance from air traffic control, the crew conducted an approach and landing at Brisbane.

Shortly after the occurrence, the ATSB issued a safety advisory notice (SAN) to operators who fly to Brisbane Airport to consider the use of pitot probe covers and, where they are used, ensure there are rigorous processes for confirming they are removed before flight.

The ATSB also uncovered a range of what it called “deeper issues”, including co-ordination among the involved organisations, that allowed front-line problems to emerge.

“Inconsistent approaches between multiple interacting organisations can have safety implications that are hard to predict,” Mitchell said.

For flight crew, the ATSB said the occurrence highlighted the importance of vigilance, communications, and decision-making in difficult circumstances.

The ATSB also found that “surprise, uncertainty, time pressure, and ineffective communication between the two pilots” during the take-off probably led to stress and high cognitive workload. This reduced their capacity to interpret the situation and make a decision early enough to safely reject the take-off.

In response, the ATSB has issued a SAN advising manufacturers and operators of all large transport aircraft to consider what types of unreliable airspeed events can occur, how the information is presented to pilots, and what responses are the safest in different phases of the take-off and in a range of potential situations.

All of the relevant organisations have contributed to the large number of safety actions taken in response to the incident and the ATSB’s investigation.

For example, the ATSB said Malaysia Airlines now requires the placement of a placard on the flight deck as a visual alert that pitot probe covers are in place, and has introduced improvements to its change and risk management processes.

Airbus, meanwhile, has implemented additional flight crew training standards about unreliable airspeed on take-off, added guidance to the flight crew techniques manual on the importance of airspeed monitoring on take-off, and has commenced a review of airspeed indications in A330 and other aircraft types.

The ground handling and engineering companies involved in the incident have also made system and process improvements, and the airport information provided to pilots has been amended.

“The cooperation of all involved organisations has been very encouraging, especially the amount of safety action they have undertaken,” said Mitchell.

“Many safety gaps have been addressed as a result of this extensive investigation.”

lionel young

says:Surely in this day and age these Pito tubes could be made to retract and a small hatch close when the aircraft turns off and extends when the engines are started ,not rocket science

Marum

says:One problem does not usually cause a crash, but a build up of several often do.

Malaysian Air, has proven to be too slipshod for my liking….Marum.

Paul Blackshaw

says:An incident like this is unfathomable. BOTH pilots , a ground engineer, a tug driver all failed to see pilot covers and then a take off with unreliable airspeed ensued. What can be said?

Nerdy Nev

says:Do you mean the ‘pilots’ caps’?

Maybe you meant ‘pitot’……read comment before posting is a good rule.

Marum

says:Malaysia Air is certainly a slipshod outfit. Did anyone notice all the other faults with the aircraft?

How many people do the have to kill? They should be banned from Australia. I would not fly with them if the paid me.

Regards….Marum.

Wilson

says:I know nothing about aircraft. The article suggest that covered pitot probe can cause fatal air crash. Is it too difficult to indicate in cockpit dashboard display if the pitot probe is covered? By the look of it checklist over checklist by various people is not going to solve the problem.

phil

says:Added wight in an era of lightening the load / mass. Besides .. WHAT IF .. the pitot doesn’t deploy, OR deploys incorrect etc .

jusingh

says:im thinking what happens if it doesnt retract during shutdown? or retracts while inflight?

Colin Earl

says:Why not simply have a plug on a lanyard attached to the covers, that is plugged into the aircraft and signifies that the covers are in place. Then messages can be dsiplayed to the pilots and/or takeoff inhibited or whatever is needed.

My patent-free contribution to aviation. 🙂

Adrian P

says:Basic errors like this will continue to happen as long as airlines persist in outsourcing their ground services to multiple agencies..

Heston MRO implemented procedures to improve the consistency of pitot probe cover use and tool control measures.

Menzies Aviation implemented improvements to its internal auditing programme.